Product description:

Zirconium carbide (ZrC) is an important high-temperature structural material with high melting point, high strength and corrosion resistance, and has the characteristics of efficiently absorbing visible light, reflecting infrared and energy storage and heat storage. It is widely used in aviation, aerospace, cermet and New types of thermal insulation and temperature regulation textiles and other fields.

1. Modifier of carbon-carbon composite functional materials-zirconium carbide (ZrC): zirconium carbide modified carbon fiber can greatly improve the strength of carbon fiber, increase the fatigue resistance, wear resistance and high temperature resistance. At present, it is widely used in the modification of aerospace carbon fiber materials, and the effect is very obvious. The modified carbon fiber has been tested and all indicators have caught up with foreign standards.

2. Zirconium carbide (ZrC) is used in the field of new thermal insulation and temperature-regulating textiles: Zirconium carbide has the characteristics of efficiently absorbing visible light and reflecting infrared. When it absorbs 95% of the sunlight in the short-wavelength energy below 2μm, through thermal conversion, energy can be stored in the material, and it also has the characteristic of reflecting infrared wavelengths of more than 2μm. The wavelength of infrared rays produced by the human body is about 10 μm. When people wear modified textile clothes containing zirconium carbide, the infrared rays of the human body will not easily radiate outward. This shows that zirconium carbide has ideal heat absorption and heat storage characteristics;

3. Zirconium carbide (ZrC) is used in cemented carbide, powder metallurgy and other fields to improve the strength and corrosion resistance of cemented carbide;

4. Zirconium carbide (ZrC) is used as a modifier of solid propellant grains for rockets and missiles.

Performance characteristics:

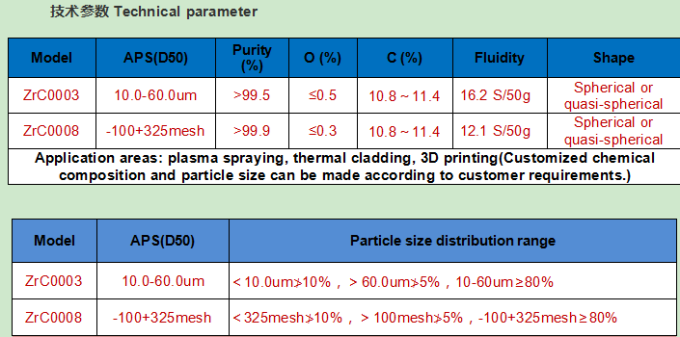

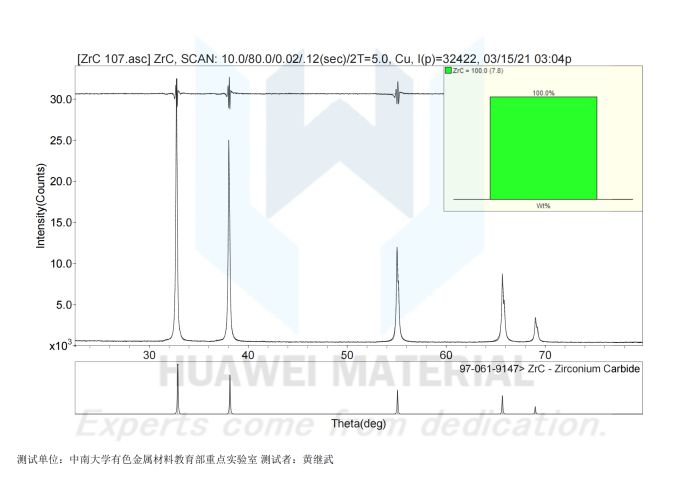

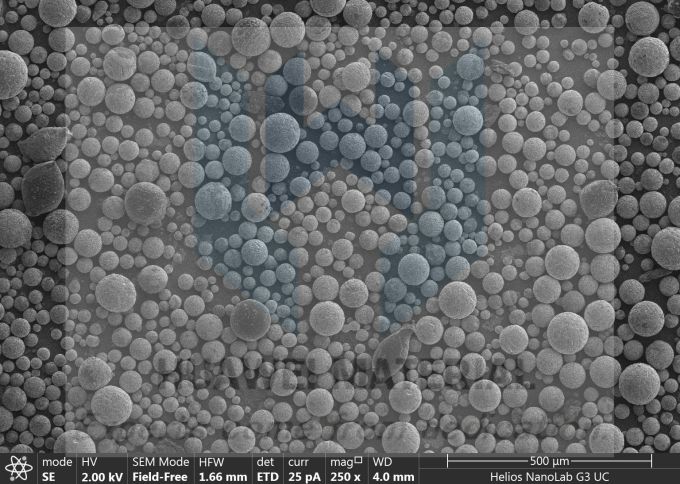

1. High purity, no impurity phase detected by XRD, low content of metal impurity elements detected by GDMS/ICP;

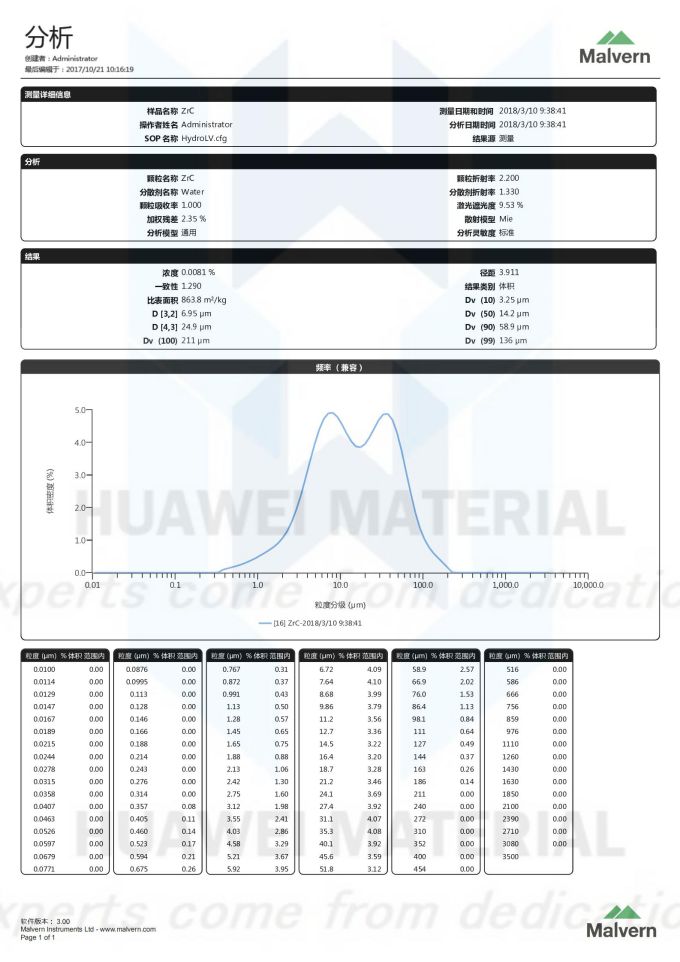

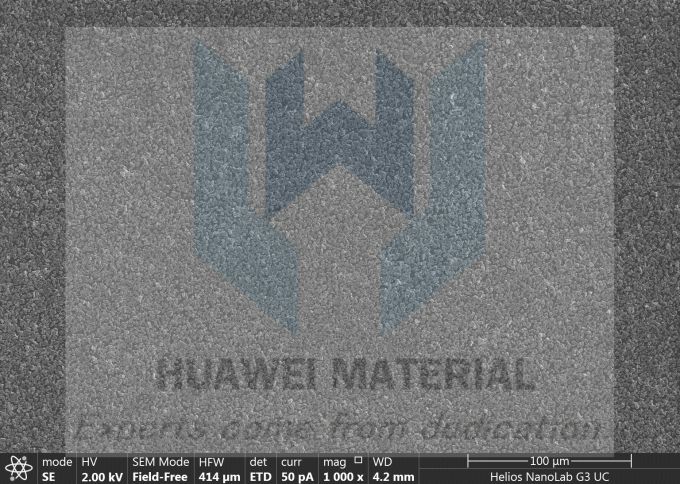

2. Concentrated particle size distribution, good sphericity, good fluidity, no tube blocking, good quality of 3D printing and thermal spraying.

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)