Production Information:

Hafnium diboride (HfB2) is a new type of ceramic material with high melting point, high thermal conductivity, oxidation resistance and other high-temperature comprehensive properties. It is mainly used in ultra-high temperature ceramics, high-speed aircraft nose cones, aviation, aerospace and other fields. Hafnium diboride (HfB2) is mainly used as a modifier for carbon-carbon and carbon-ceramic composite functional materials: Hafnium diboride (HfB2) modified carbon fiber can greatly improve the strength of carbon fiber, increase fatigue resistance and wear resistance And high temperature resistance, the modification effect is very obvious, and all indexes are greatly improved.

Performance Character:

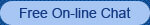

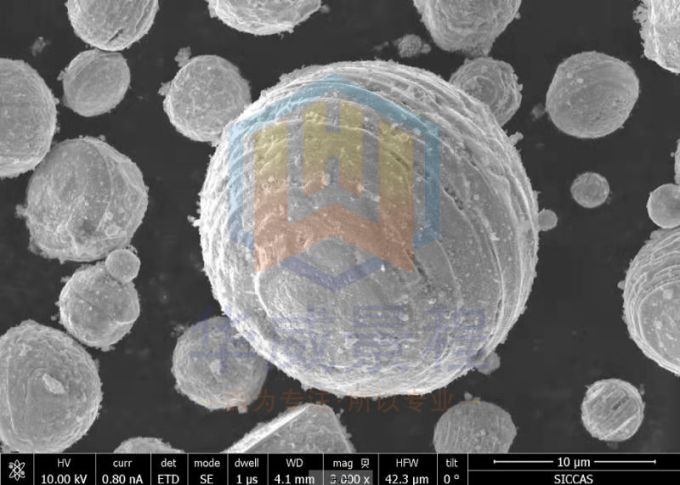

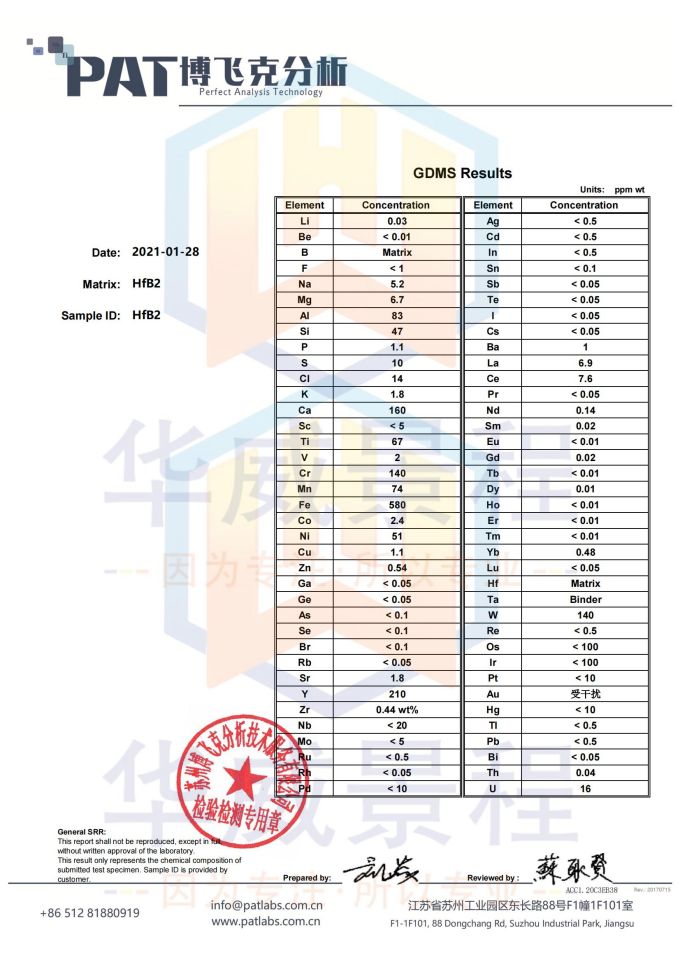

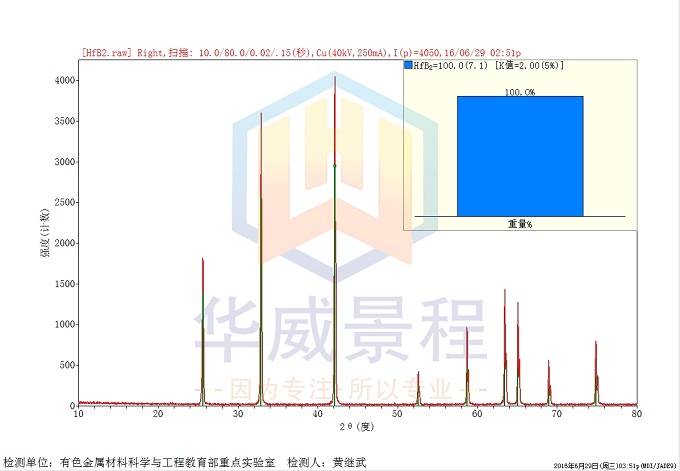

1. High purity: the highest purity can reach 99.99%, XRD detect no impurity phase, GDMS detect low metal impurity element content;

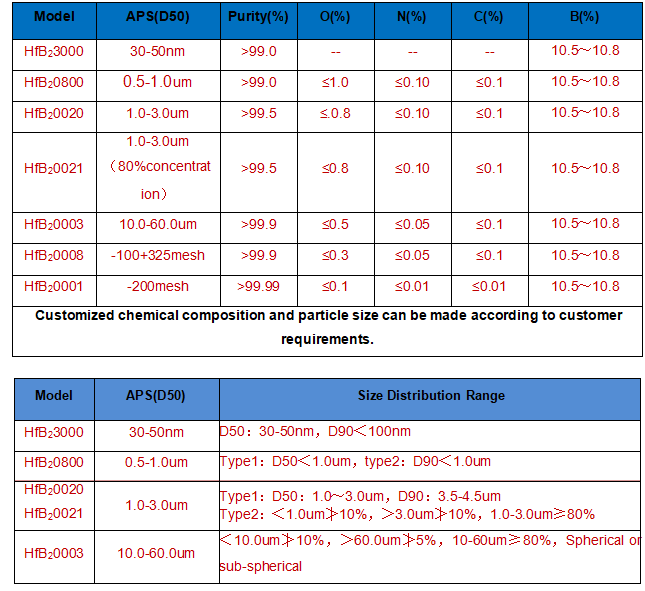

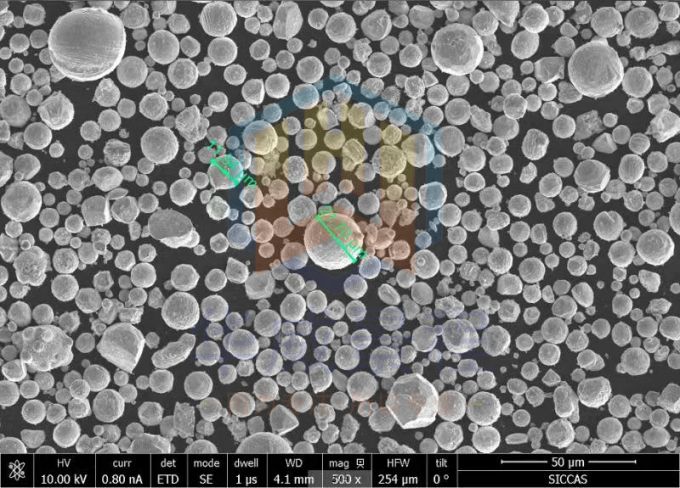

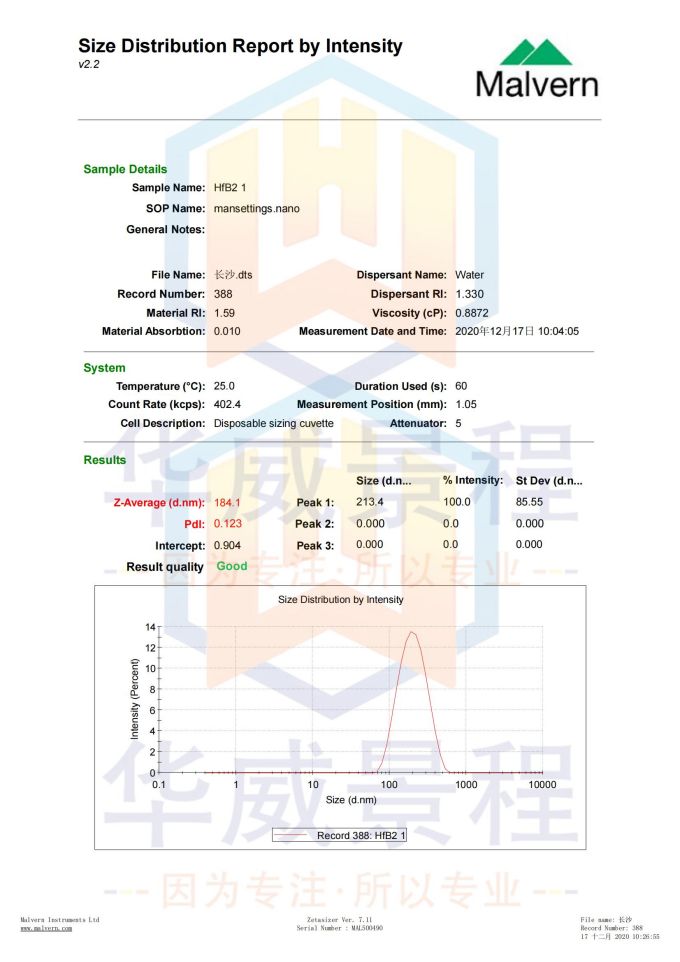

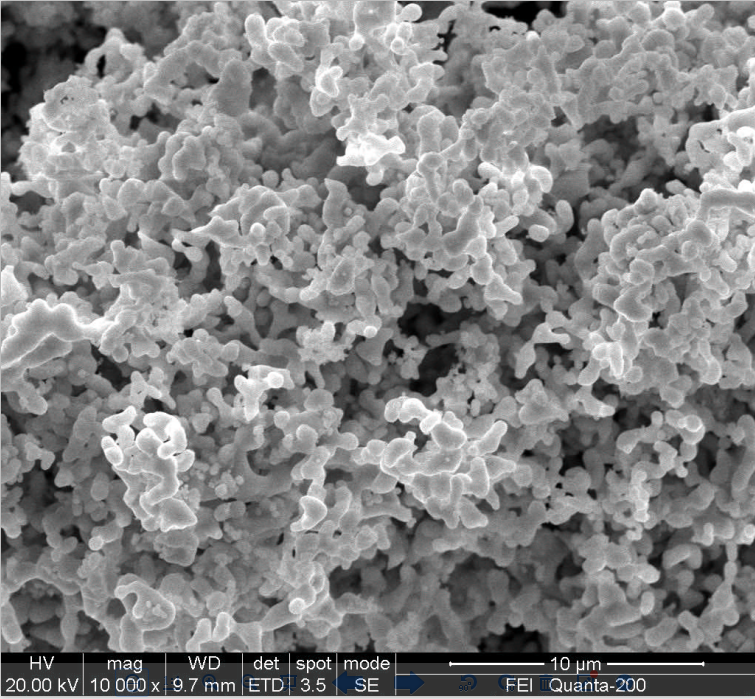

2. Small particle size: the smallest particle size is 30-50nm;

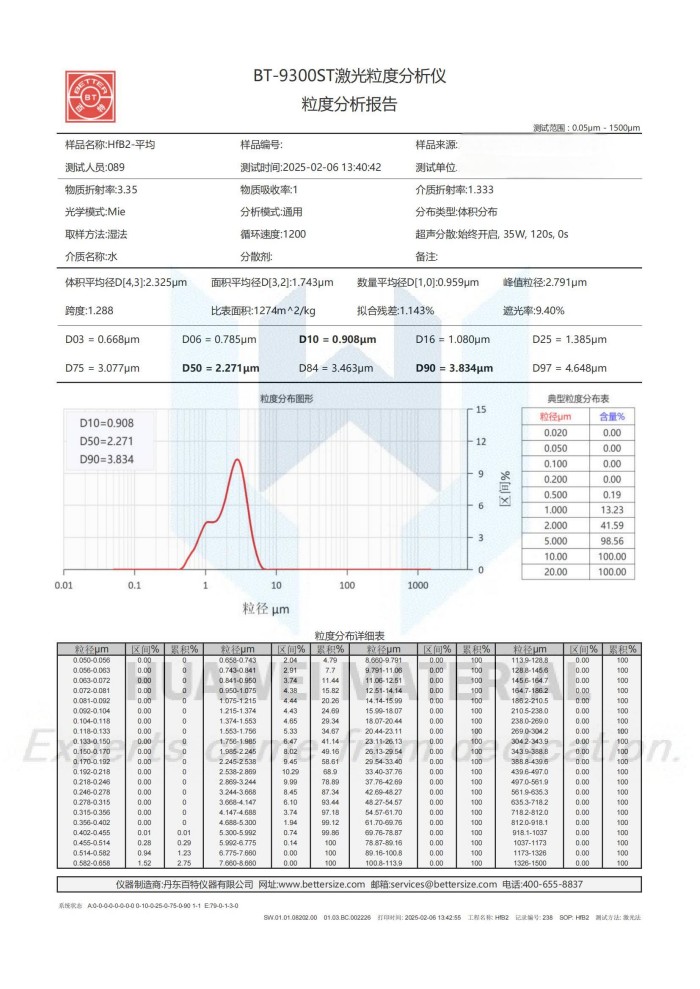

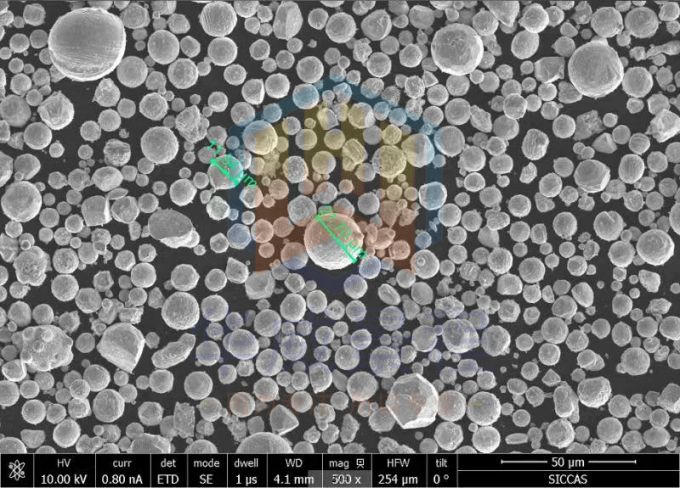

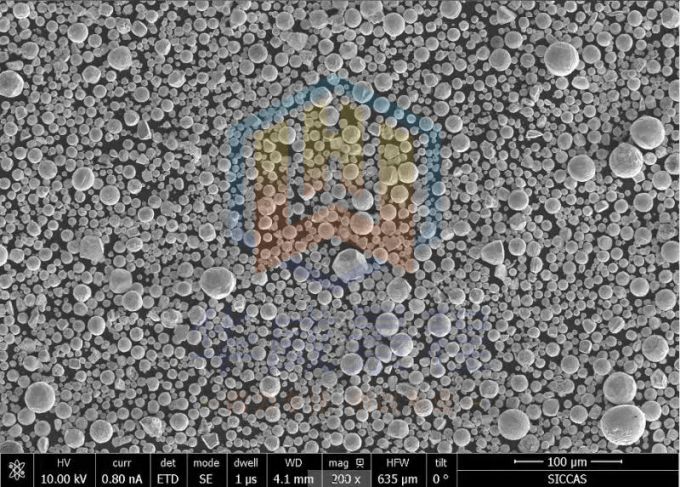

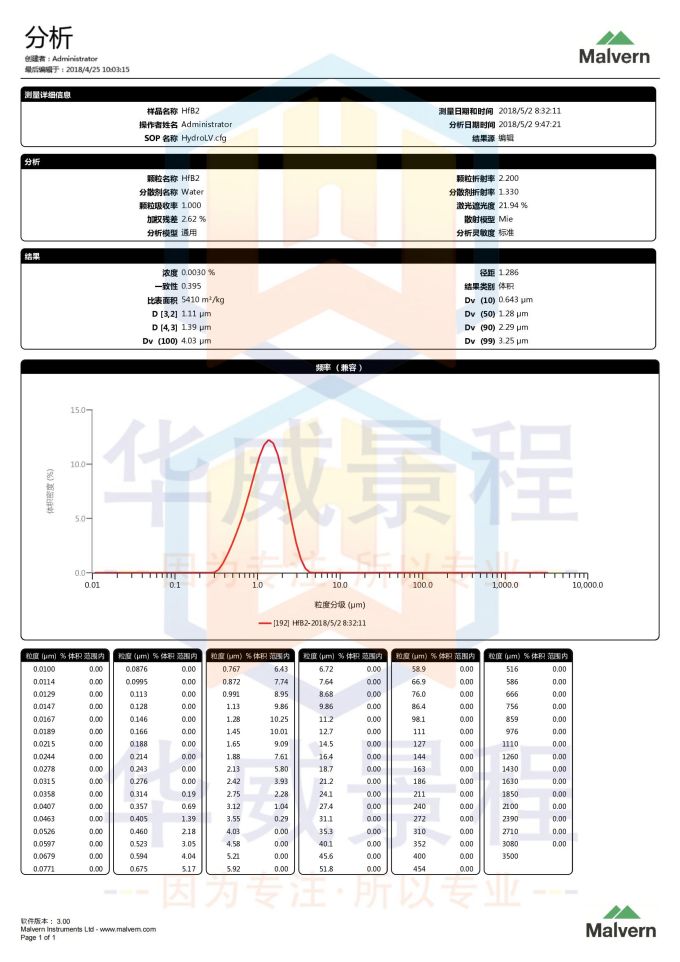

3. Concentrated distribution: standard normal particle size distribution, no bimodal or multimodal.

4. Typical application:

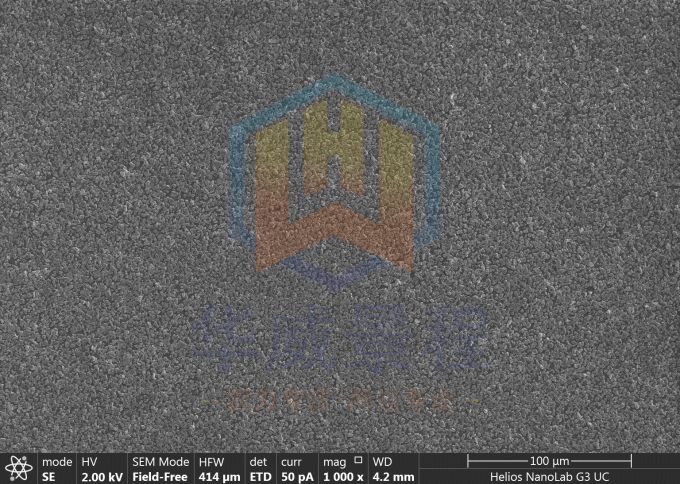

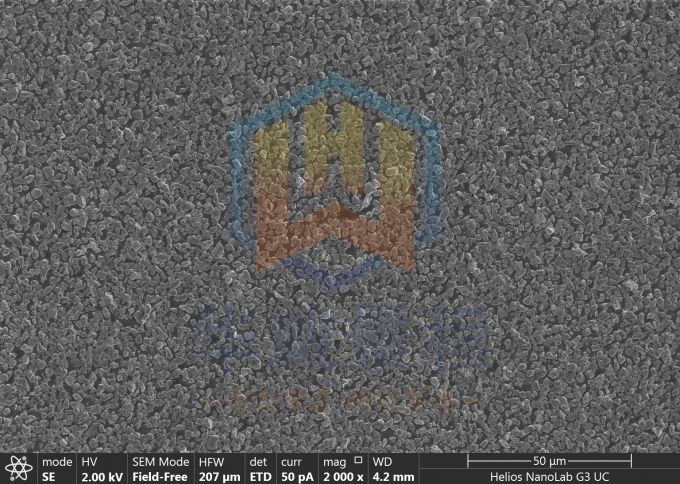

①Standard 1-3um (D10>1.0um, D50: 1.2~1.8um, D90<3.0um, 80% of the particle size is concentrated in the range of 1-3um)

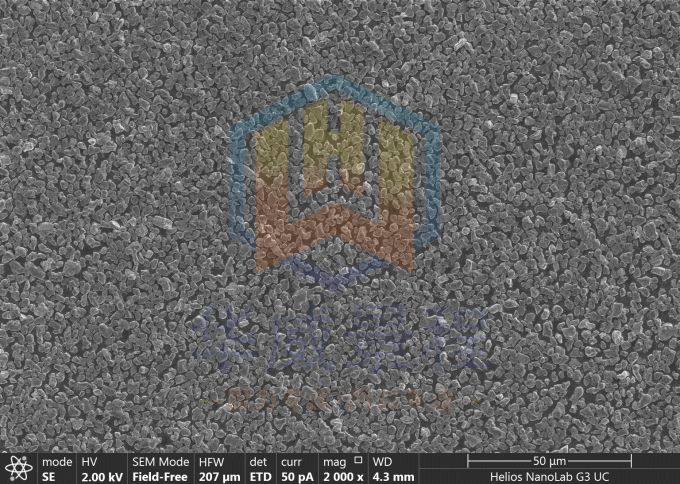

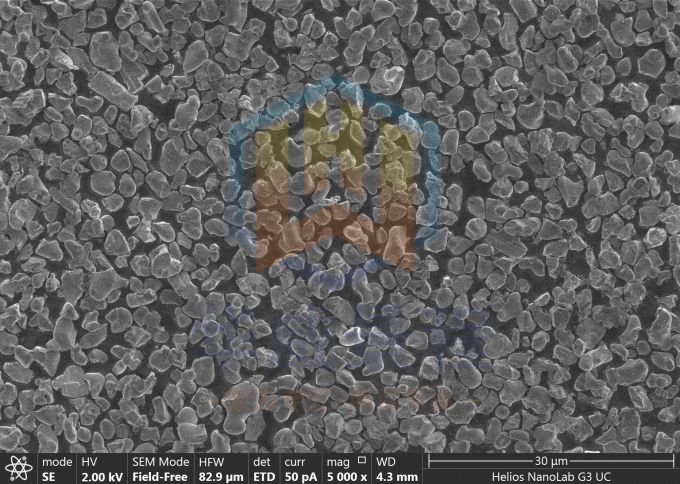

②10-60um Plasma thermal spraying cermet powder(D10>10.0um,D50:20~30um,D90<60.0um,80%of the particle size is concentrated in the range of 10-60um )

(Chat Online)

(Chat Online)