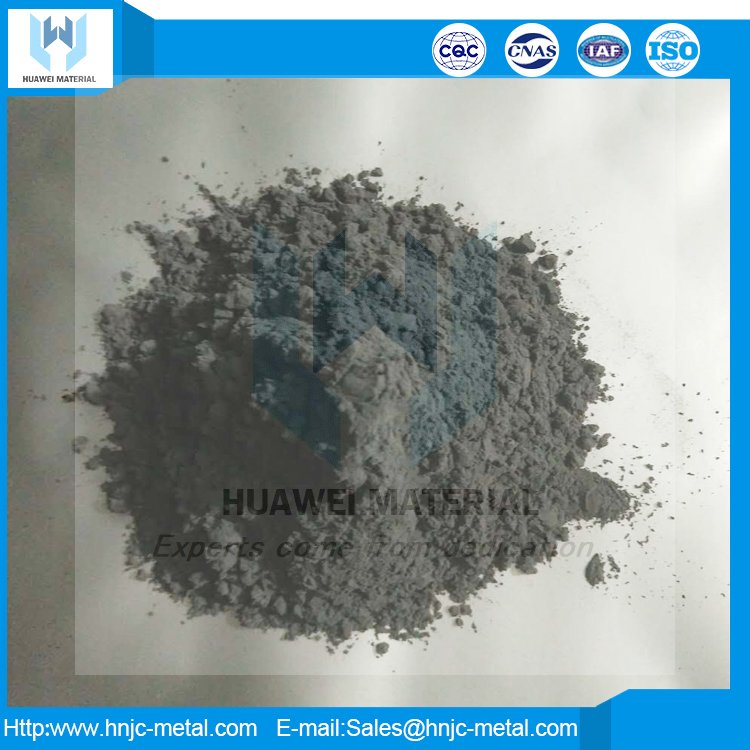

Production information:

Molybdenum boride (MoB2/MoB) has high hardness and low relative friction coefficient, chemical stability, wear resistance and corrosion resistance. This material is used on sliding friction surfaces to reduce wear. Molybdenum boride has a high melting point (2600℃), excellent wear resistance, heat resistance and oxidation resistance. It can be used for high temperature spray coatings, cermets, wear resistance coatings, high temperature resistances, crucible linings, filling spraying and Corrosion-resistant chemical equipment.

Performance character:

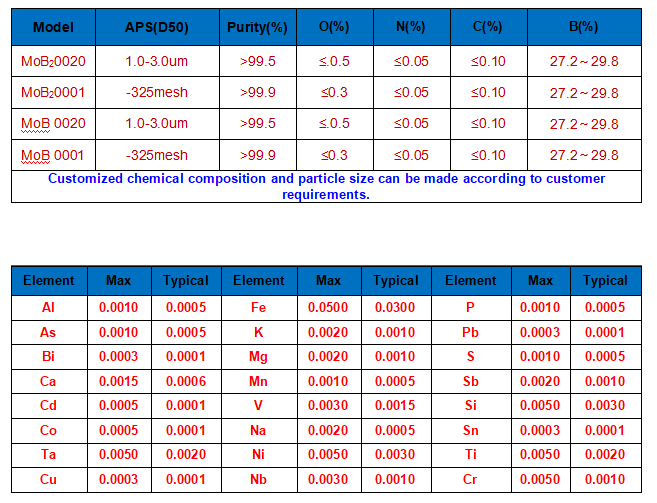

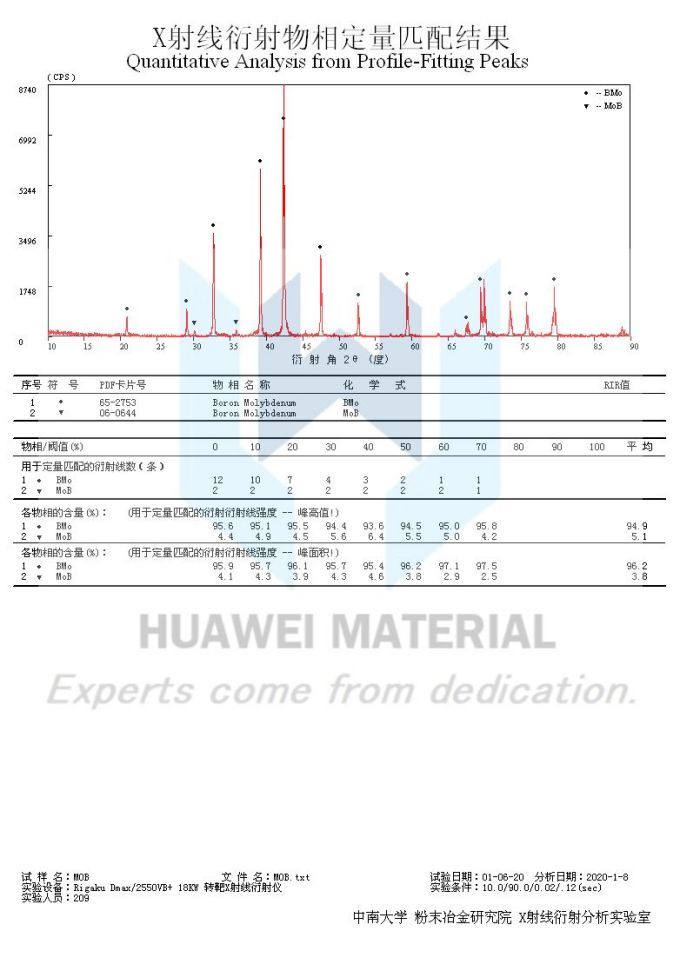

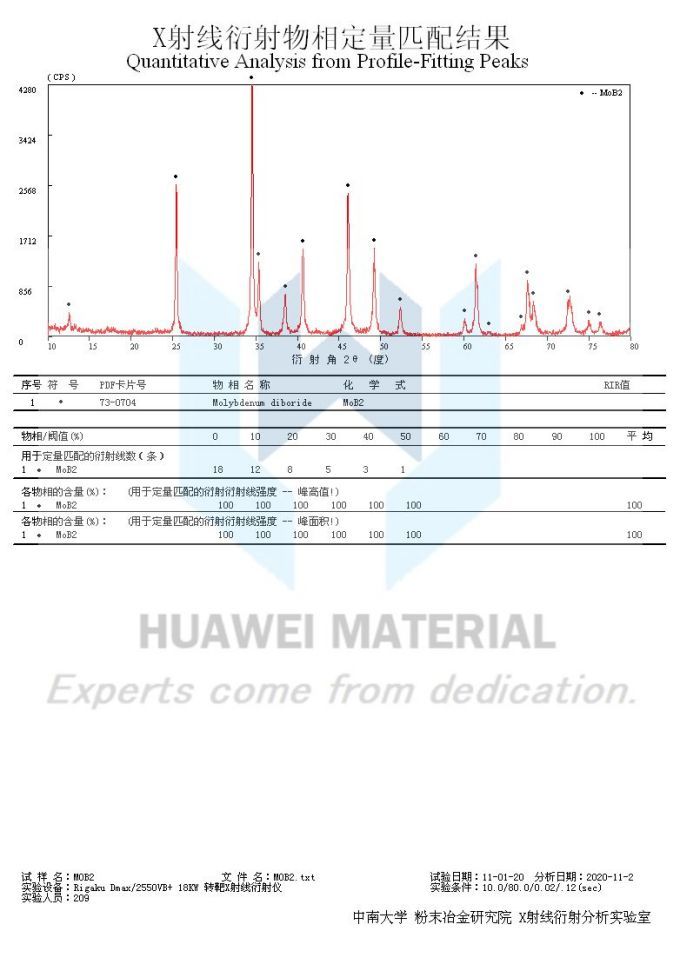

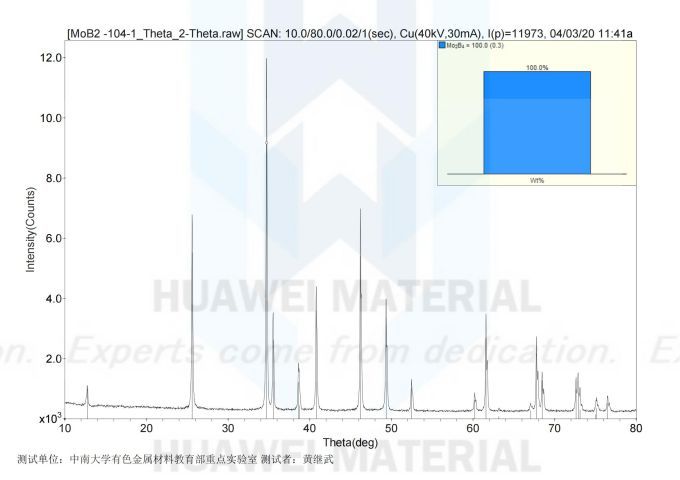

1. High purity: the highest purity can reach 99.99%, XRD detect no impurity phase.

2.Concentrated distribution: standard normal particle size distribution, no bimodal or multimodal.

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)