Product overview:

Titanium carbide is a typical transition metal carbide. It has high temperature resistance, oxidation resistance, high strength, high hardness, good thermal conductivity, good toughness. Its ultraviolet light shielding is greater than 80%, and it has good electrical conductivity.In addition, its chemical inertness to iron and steel metals and other excellent properties make it a nano materials with great application value, which are used in spraying materials, welding materials, hard film materials, military aviation materials, cemented carbide and cermets.

Application areas:

1. The field of metal matrix composite materials: abrasives and abrasive tools industry, metal ceramic composite coating, electrical contact head coating materials, ceramic blades.

2. Powder metallurgy field: Titanium carbide powder is used as raw material for powder metallurgy production of ceramics and cemented carbide parts, such as wire drawing dies, cemented carbide molds, etc.

3. Cermet industry: cermet with Nano-TiC (Nano-TiC) added has better strength, hardness, thermal conductivity, electrical conductivity and heat resistance.

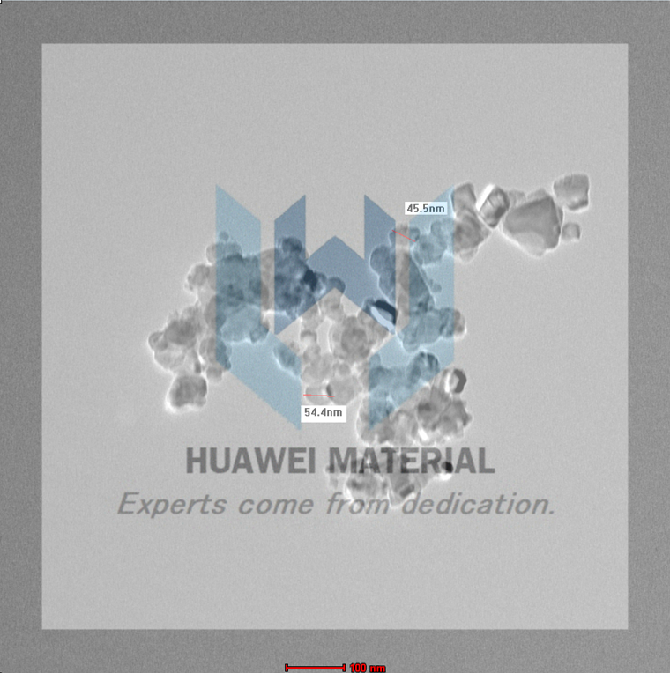

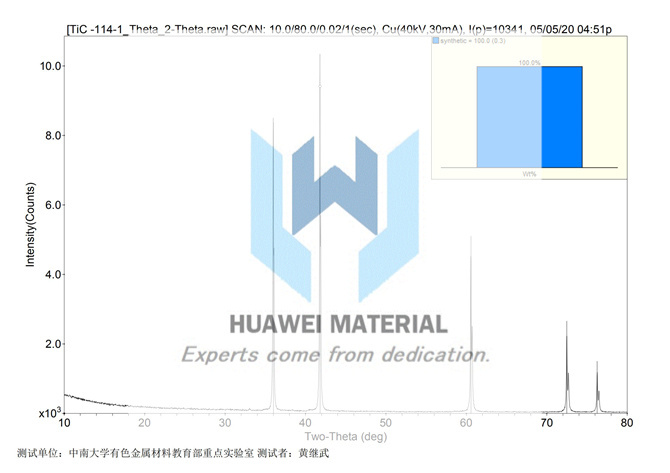

Performance characteristics: Nano-TiC has the characteristics of high purity (no impurity phase detected by XRD), small particle size (50nm), large specific surface area, and high surface activity.

Precautions:

This product should be stored in a cool and dry room to avoid heavy pressure. During use, it shall not be exposed to the air to avoid moisture absorption and agglomeration, which will affect the dispersion performance and use effect. Unpacked products shall be sealed or stored in vacuum.

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)