Product overview:

MoSi2=152.12, density: 6.26 g/cm3, melting point :2030°C, conductive,at high temperature, a passivation layer of silicon dioxide can be formed on the surface to prevent further oxidation, and its appearance is gray metallic color.

MoSi2 is an intermediate phase with the highest silicon content in the Mo-Si binary alloy system. It has the dual characteristics of metal and ceramics. Therefore, molybdenum disilicide has good high-temperature oxidation resistance, high-temperature plasticity, thermal conductivity and fluidity. It has a wide range of applications in the field of high-temperature structural ceramics.

MoSi2 is mainly used as heating elements, integrated circuits, high-temperature anti-oxidation coatings and high-temperature structural materials. Molybdenum disilicide is used as a structural material for high-temperature parts of aviation, aerospace, and automobile gas turbines.

Performance characteristics:

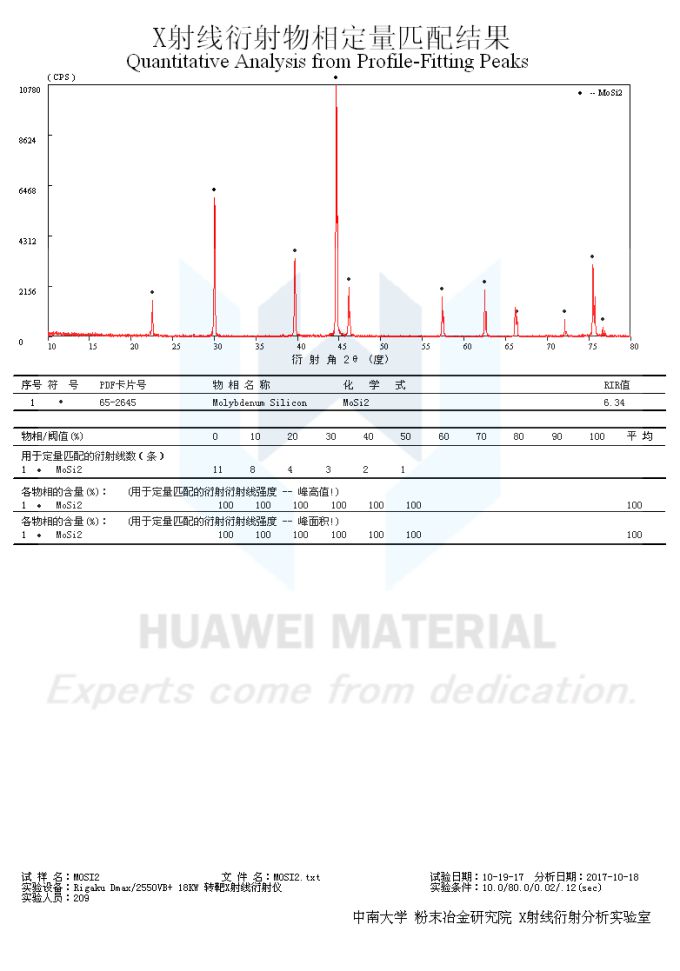

1. High purity, no impurity phase detected by XRD, low content of metal impurity elements detected by GDMS/ICP;

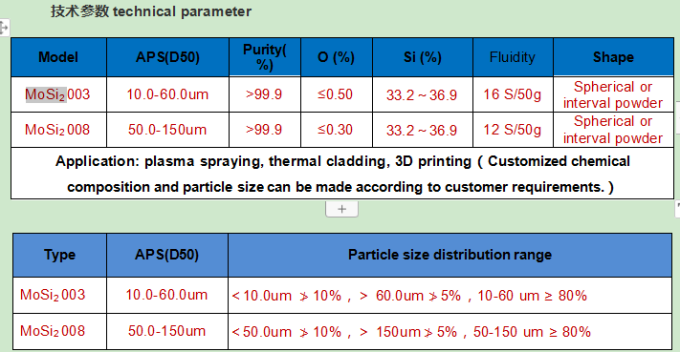

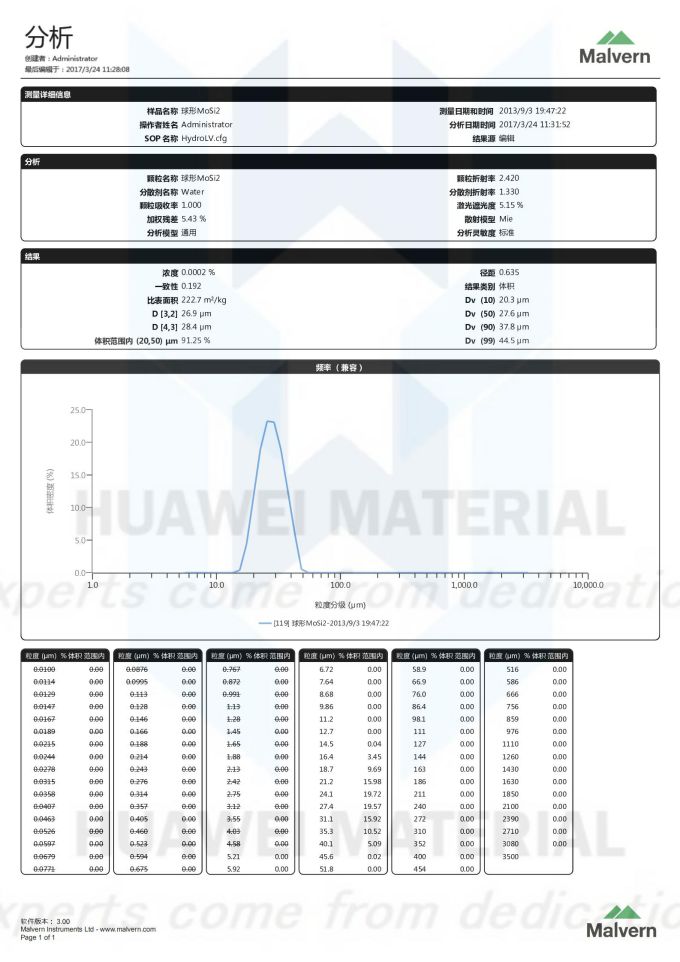

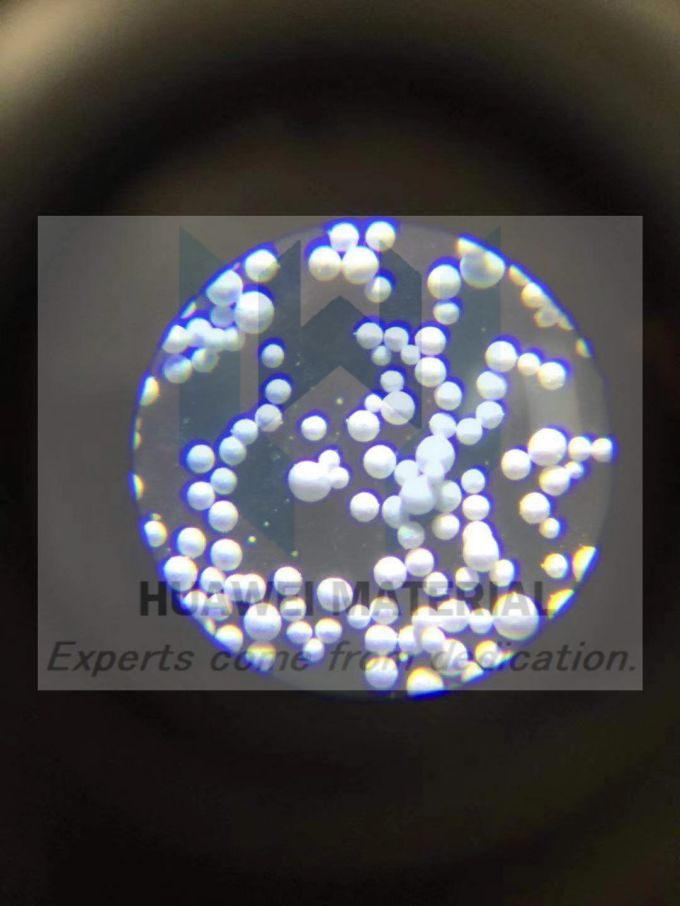

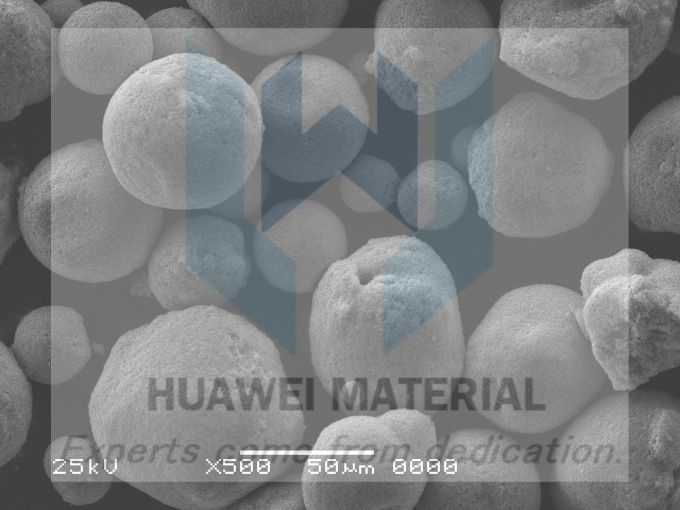

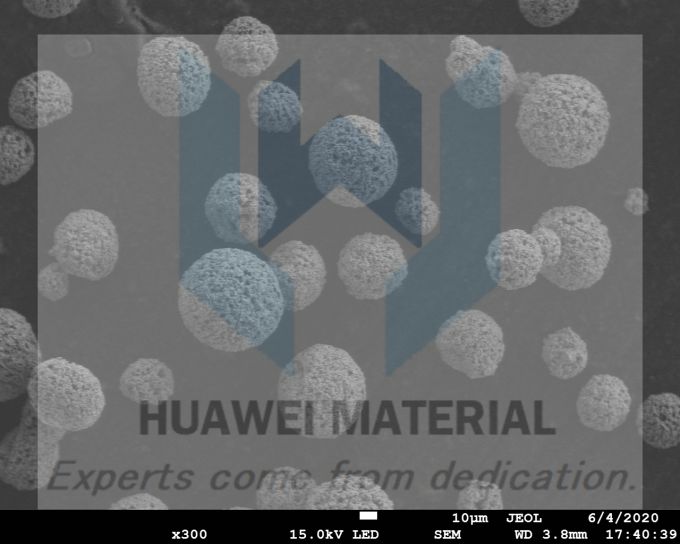

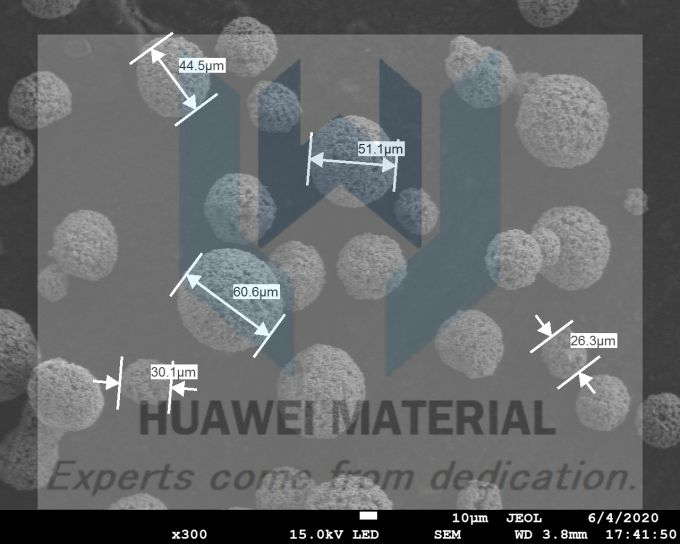

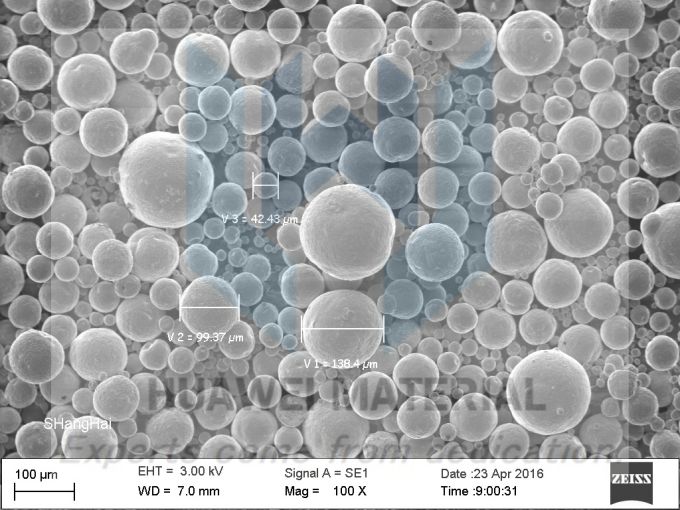

2. Concentrated particle size distribution, good fluidity, no pipe blockage, and excellent thermal spraying quality.

3. Concentrated distribution: standard normal particle size distribution,particle size distribution range can be designed according to customer requirements;

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)