Product overview:

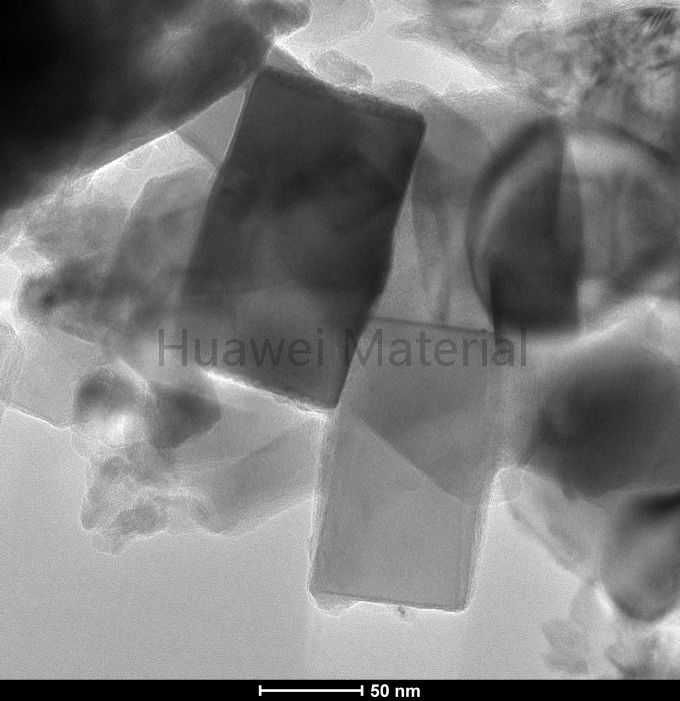

Gray metallic powder, with NaCl type cubic crystal structure, has the highest melting point among known single compounds. Hafnium carbide has a high coefficient of elasticity, good electrical and thermal conductivity, a small coefficient of thermal expansion and good impact resistance. It is widely used in cemented carbide, aerospace, atomic energy, electronics, coatings and hard films, etc. In the field of material technology, it is the most important basic material for the manufacture of missiles, launch vehicle nozzle throat linings, satellites, and spacecraft hood parts for thermal protection.

1. Hafnium carbide (HfC) can be used as a modifier for carbon-carbon and carbon-ceramic composite functional materials: hafnium carbide (HfC) modified carbon fiber can greatly improve the strength of carbon fiber, increase fatigue resistance and wear resistance and high temperature resistance. The performance and modification effect are very obvious, and all indexes are greatly improved.

2. Hafnium carbide (HfC) is used in cemented carbide, powder metallurgy and other fields, which can improve the strength and corrosion resistance of cemented carbide, and the effect is more obvious than that of zirconium carbide (ZrC);

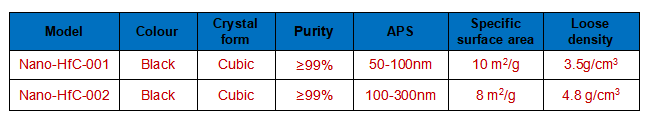

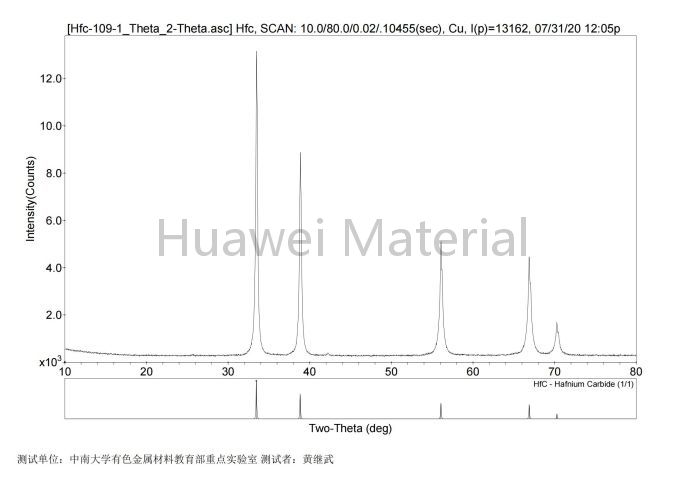

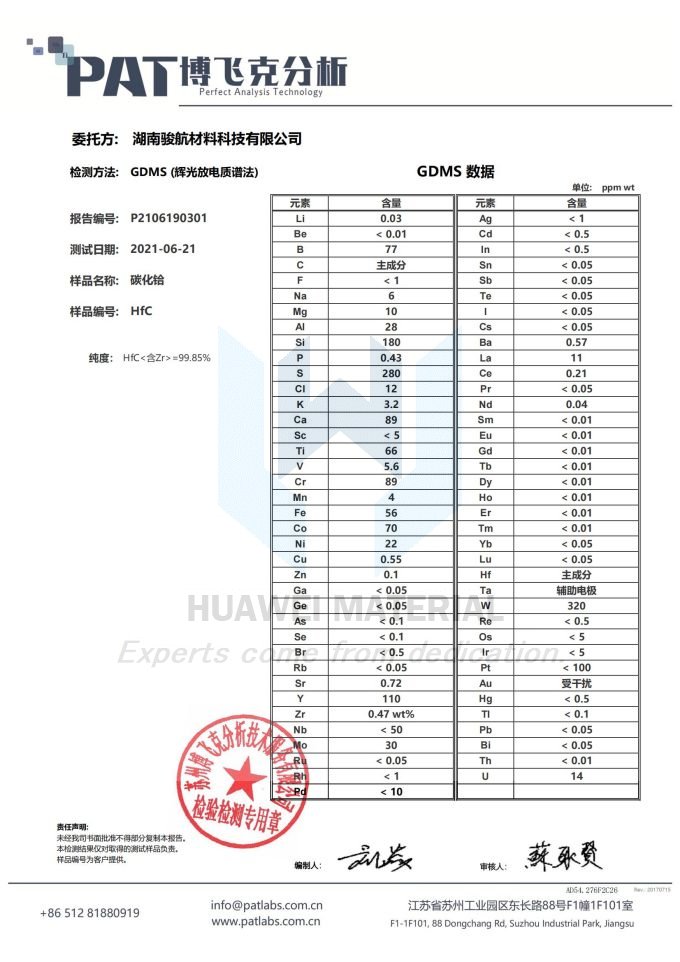

Performance characteristics: Nano-HfC (Nano-HfC) has the characteristics of high purity (XRD detected no impurity phase), small particle size (50nm), large specific surface area, and high surface activity.

Precautions:

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)