Product overview:

Nickel silicide (Ni2Si), used as the cathode of N-type thermocouples, has good thermoelectric stability above 1000 ℃ and has better oxidation resistance than that of E,J and K typesthermocouples.

In the field of semiconductor materials, a variety of metal silicides have been studied for the contact and interconnection technology of semiconductor devices. MoSi2, WSi2 and Ni2Si have been successively introduced into the development of microelectronics devices. The silicon-based film of metal silicides has a good match with the silicon material itself, and it can be used for insulation, isolation, passivation and interconnection in silicon components. The formation process of nickel silicide (Ni2Si) has low silicon consumption and low formation heat budget, low resistivity and no linewidth effect, so Ni2Si, as a nanoscale device, has been widely concerned and studied.

In graphene electrode, nickel silicide can delay the silicon electrode pulverization, cracking, and improve the conductivity of the electrode.

What’s more, Ni2Si alloy has wetting and spreading effect on SiC ceramics at different temperatures and atmospheres.

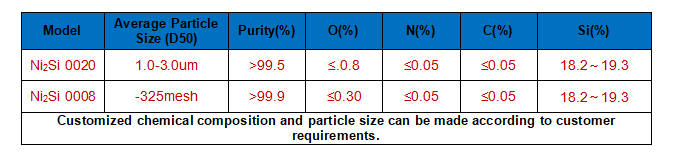

Performance characteristics:

1, High purity: XRD detected no impurity phase;

2. Concentrated distribution: standard normal distribution of particle size, no bimodal or multi-modal.

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)