Product overview:

1. High chemical stability, low thermal expansion coefficient, high thermal conductivity, and the resistance temperature characteristic is opposite to that of metal;

2. High hardness, Mohs hardness up to 9.5, is the preferred material for wear-resistant additive;

3. Wear resistance, high temperature resistance, corrosion resistance, acid and alkali resistance solvent, widely used in coatings and paints to increase wear resistance;

4. It has good toughness, excellent grinding performance and good scattered electric and thermal conductivity.

Application direction

1. Modified high-strength nylon material: the tensile strength of high-strength nylon alloy modified by nano SiC powder is 150% higher than that of ordinary PA6, and the wear resistance is 3 times higher. It is mainly used for polymer parts of armored tracked vehicles, automobile steering parts, textile machinery, lining plates of mining machinery and other parts;

2. Wear resistance of modified special engineering plastic PEEK: when adding 5% nano silicon carbide, the wear resistance of PEEK can be greatly improved (> 30%);

3. Wear resistance of modified rubber tire: adding 2% nano silicon carbide can improve the wear resistance by 20% - 40% without reducing its original performance and quality;

4. Nano SiC composite coating on metal surface: it adopts the second mixed particle of nano particles and nickel as the matrix metal to form an electrodeposited composite coating with high density and high adhesion on the metal surface. Its metal surface has the characteristics of superhard (wear resistance) and wear reduction (self lubrication) and high temperature resistance. The microhardness of the composite coating is greatly improved, the wear resistance is increased by 2-3 times, the service life is increased by 3-5 times, the adhesion between the coating and the matrix is increased by 40%, the coverage ability is strong, and the coating is uniform, smooth and meticulous;

5. Precision structural ceramic devices: such as sliding bearings, liquid fuel nozzles, crucibles, high-power and high-frequency molds, semiconductor components used in metallurgy, chemical industry, machinery, aerospace and energy industries.

6. Other applications: high performance structural ceramics, microwave absorbing materials, anti-wear lubricating grease, high-performance brake pads, high hardness and wear-resistant powder coatings, composite ceramics, reinforcement and toughening, etc; Structural coatings, functional coatings, protective coatings, microwave absorbing materials, stealth materials, etc. in the field of aerospace industry; Protective armor of tanks and armored vehicles; It can be used as ceramic cutting tools, cutting tools, measuring tools and molds; Structural ceramics, functional ceramics and engineering ceramics that can be used for special purposes; Igniter; Electric heating element for electrical industry, far infrared generator.

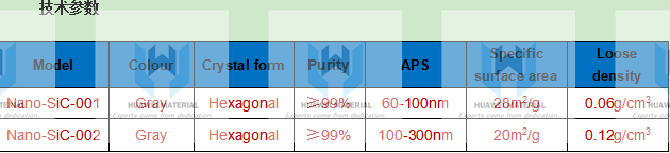

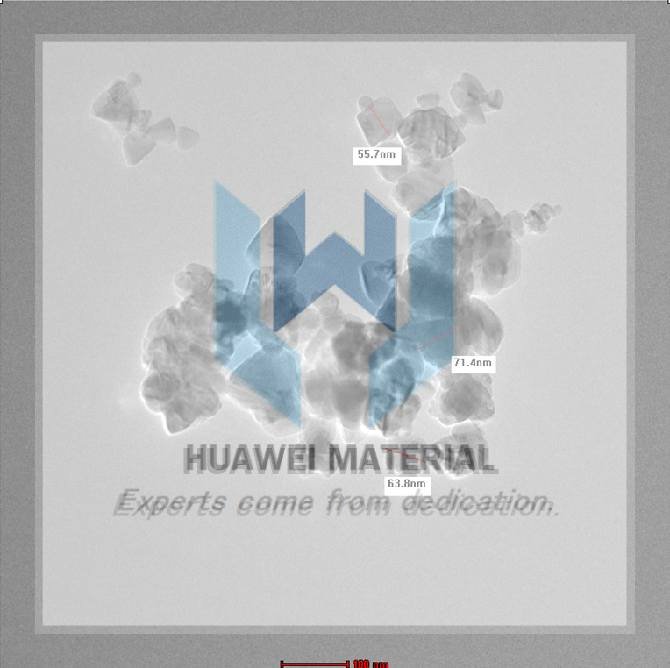

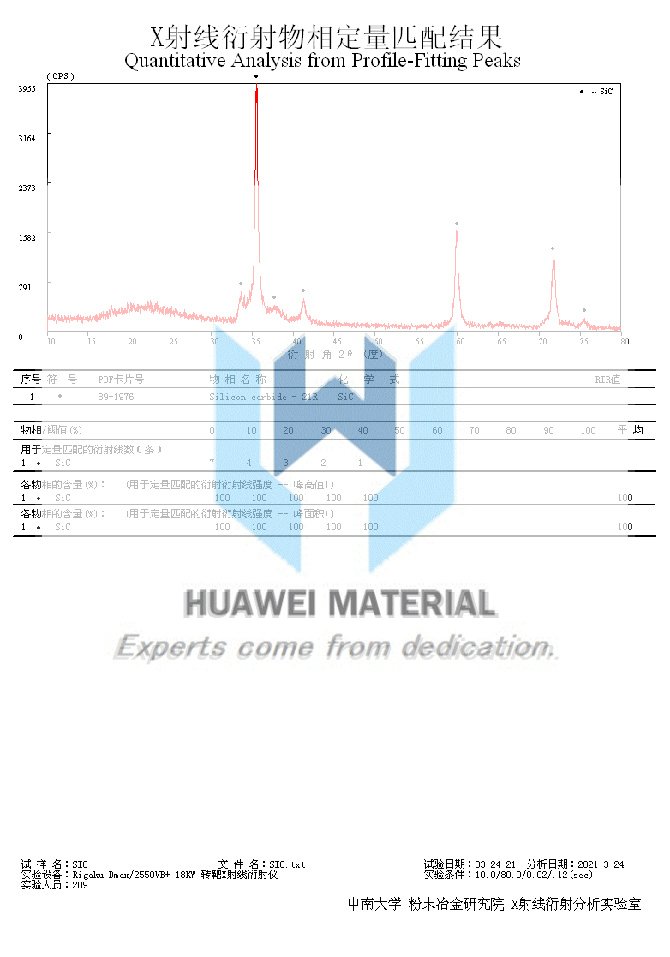

Performance characteristics: nano SiC has the characteristics of high purity (no impurity phase detected by XRD), small particle size (60NM), large specific surface area and high surface activity.

Precautions:

- 3D print&thermal spray series

-

- thermal spray Niobium carbide-N

- thermal spray Hafnium carbide-H

- thermal spray vanadium carbide-

- thermal spray Zirconium Diborid

- 3D printing spherical tantalum

- thermal spray Hafnium Nitride -

- thermal spraying Zirconium Nitr

- thermal spray Titanium diboride

- 3D printing spherical titanium

- thermal spray Niobium powder-Nb

(Chat Online)

(Chat Online)