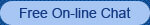

1. Nano-zirconium carbide

Nano-zirconium carbide powder possesses high purity, small particle size distribution, and high specific surface area. This product has a high temperature oxidation resistance, strength, high hardness, good thermal conductivity. It is an important structural material. Nano-zirconium carbide powder also has a high absorption of Visible light,reflectance of infrared light,energy storage.

2. Nano-titanium carbide

Nano-titanium carbide powder possesses high purity, small particle size distribution and high specific surface area. The melting point is about 3200℃, which is an essential component of cemented carbide with high hardness corrosion resistance, and thermal stability. And can be applied in manufacture of wear-resistant materials, cutting tools, mold, metal melting crucible, and many other fields. As small particle it has high surface activity, good conductivity, and chemical inert ability to steel and iron.

3. Nano-titanium nitride

Nano-titanium nitride powder possesses high purity, small particle size distribution, and high specific surface area. Nano-titanium nitride has a high melting point(2950℃), high hardness, high chemical stability and good thermal conductivity.

4. Nano-Silicon carbide

Nano-Silicon carbide powder possesses high purity, small particle size distribution and high specific surface area and so on. The product has high chemical stability, good thermal conductivity, small thermal expansion coefficient and good abrasion resistance. The micro hardness is about 2840-3320kg/mm2, its hardness is between corundum and diamond while the mechanical strength is higher than corundum. Nano-SiC has excellent thermal conductivity and is large band gap semiconductor. When in high temperature it can be resistant to oxidation.

5. Nano-silicon powder

Nano-silicon powder possesses high purity, small particle size distribution and high specific surface area. The melting point can reach up to 1410℃, while boiling point at 2335℃, and ionization energy 8.15 EV. Nano-silicon powder is non-toxic, odorless, high s surface activity, which is a new generation of photoelectric semiconductor materials with wide energy gap. It can also be used as power light source materials.

6. Nano-boron carbide

Nano-boron carbide powder possesses has high purity, small particle size distribution and high specific surface area. Nano- boron carbide melting point can reach up to 2350℃, boiling point>3500℃hardness is 9.3,flexural strength≥400Mpa. The product can not react with acid and alkali, with high chemical potential, which is one of the most stable substances to acid. And also has good quality of high temperature, high strength, high grinding efficiency and good self-lubrication. Its ability to absorb neutrons without forming long lived radionuclide makes the material attractive as an absorbent for neutron radiation arising in nuclear power plants. Nuclear applications of boron carbide include shielding, control rod and shut down pellets. Within control rods, boron carbide is often powdered, to increase its surface area.

7. Nano-zirconium diboride

Nano-zirconium diboride powder possesses has high purity, small particle size distribution and high specific surface area. Nano-ZrB2 has high melting point (3040℃), high hardness, high thermal conductivity, and high-temperature structural materials. It has metallicity, its resistance is a bit lower than the metal zirconium and has good conductivity. It is stable in a wide temperature range. Its has good oxidation resistance in air and the anti-corrosion ability of molten metal.

(Chat Online)

(Chat Online)