Ultrafine Zirconium Diboride Powders

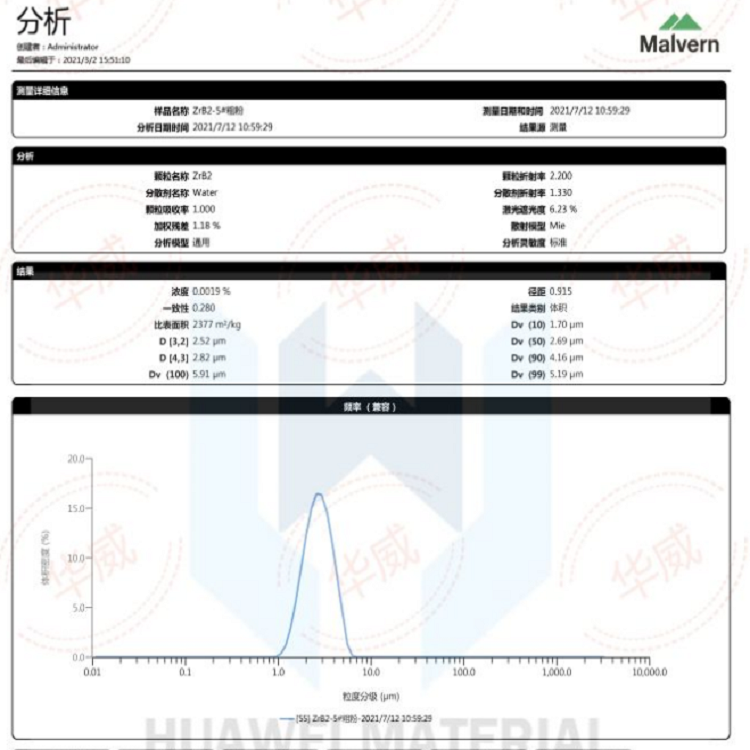

Ultrafine ZrB2 powders were successfully synthesized by using a novel method that combines the sol–gel process with the rapid synthesis of spark plasma sintering (SPS). The sol–gel method utilized a soluble zirconium-containing organic precursor consisting of zirconium n-propoxide, boric acid and furfuryl alcohol as the source materials for zirconium, boron and carbon respectably. From this precursor pure ZrB2 was successfully synthesized at 1700 °C for 5 min using the optimal molar ratios of n(B)/n(Zr) = 4 and n(C)/n(Zr) = 20. During the carbo/borothermal reductions the formation of ZrB2 occurred from the precursor prior to the ZrC and B4C formation. Therefore neither ZrC nor B4C XRD peaks were detected in the final product. It was also found that the fast heating rates employed during SPS were able to retard the grain growth of the ZrB2 particles.