The design of hypersonic flight vehicles is characterized by stringent requirements like achieving sharp leading edges to maximize lift-to-drag ratios while experiencing extreme external gas temperatures, which can reach upwards of 10,000K. Designers must contend with the reality that convective heat transfer rates between this hot gas and vehicle surface increase with decreased size of these leading edges, making most common engineering materials such as aluminum or titanium, warp, melt or even vaporize. This reality has motivated fundamental research into a new class of materials known as Ultra-High Temperature Ceramics (UHTC). These materials exhibit a unique combination of refractory and oxidation-resistant properties which allow them to survive the extreme heating environment encountered in hypersonic flight.

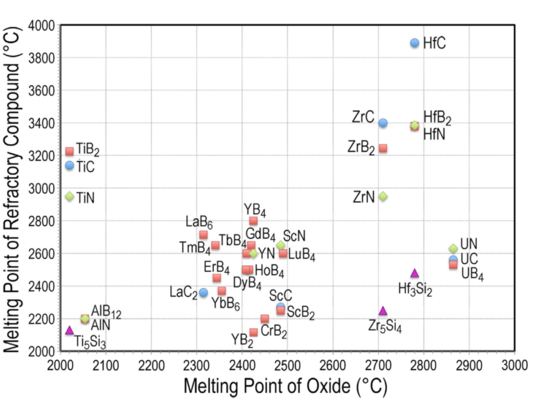

Building on the latest theories and modeling techniques available in the NGPDL, new material-environment interaction models are being explored which will aid the hypersonic vehicle designer and improve understanding of high temperature material capabilities. Of particular interest are various carbides, such as silicon-carbide (SiC) and di-borides, such as zirconium-diboride (ZrB2). A number of UHTC candidate materials are shown in the figure below, plotting each in terms of their melting point and the melting point of their corresponding oxidation states.