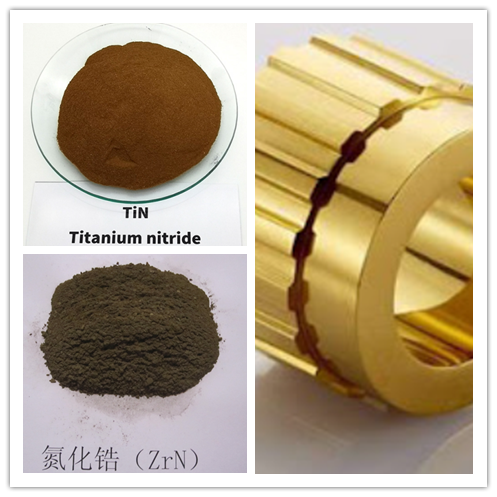

Titanium nitride (TiN) coating and zirconium nitride (ZrN) coating, due to the main elements are in the same group of the periodic table, their coating properties are also very close. However, the price of zirconium nitride is higher than that of titanium nitride, so it becomes a minority coating and is not common.

The effect of zirconium nitride without droplets is better than that of titanium nitride

Zirconium (Zr) is a silvery, hard, fragile metal with a high melting temperature (1852ºC) and a very high boiling temperature (4377ºC).

Titanium (Ti) is a silver-white transition metal characterized by light weight, high strength, and resistance to wet chlorine corrosion. It has a higher melting temperature (1660°C) and a higher boiling temperature (3287°C).

The high boiling point weakens the tendency of droplets to form during "unguided" arc evaporation. Therefore, the condensed film of zirconium nitride (ZrN) tends to be smoother than other refractory metals.

There are many other factors that affect droplet discharge, such as the moving speed of the cathode spot, thermal conductivity, cooling effect (affecting the average discharge surface temperature), deposition system configuration, and residues of oxides, nitrides, and metal surfaces. Coverage, or carbide. The last factor is defined by the ratio of the chemical reaction rate of the cathode material and the reactive gas present on the surface to the removal rate of the pure cathode metal and the reactive surface film ("surface poisoning").

The melting temperature of ZrN is 2980℃, which is only slightly higher than 2930℃ of TiN, and its bulk hardness is about 1500hv, which is lower than 2000hv of TiN. However, due to many unknown uncertain factors in the crystallization method of nano-coatings, the hardness of PVD-deposited ZrN coatings is often higher than that of TiN films.

Therefore, the arc-evaporated zirconium nitride (ZrN) coating is generally smoother than the titanium nitride film deposited on the surface of the workpiece under similar conditions and has higher oxidation resistance.