Due to the large specific surface area and high surface energy of nano-powders, particle agglomeration is very easy to occur in the process of preparation and use, forming secondary particles, making the particle size larger, and thus losing the functions of nano-particles. Therefore, it is necessary to disperse the nano powder.

1 Reasons for agglomeration of a nanometer powder

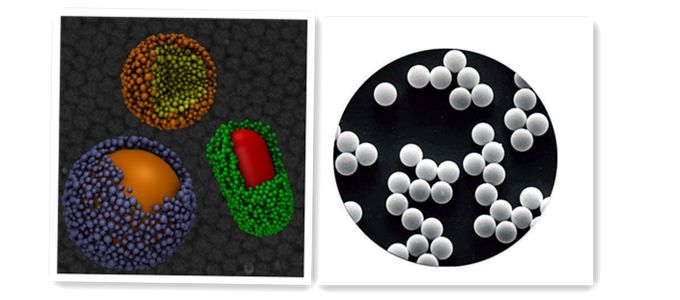

The so-called agglomeration of nano-powder refers to the phenomenon that the primary nano-powder particles are connected to each other during the preparation, separation, processing and storage process, and clusters of larger particles are formed by multiple particles. The agglomeration of powder is generally divided into soft agglomeration and hard agglomeration.

Due to the special surface structure of nanoparticles, there is an interaction energy between particles that is different from conventional particles and particles-nano interaction energy. This kind of nano-action energy is the inherent property that the surface of the nano-particle lacks adjacent coordinated atoms, which has high activity and makes the nano-particles agglomerate with each other. Its physical meaning should be the adsorption force of the nano-particles per unit specific surface area. It is the sum of several aspects of the adsorption of nanoparticles: adsorption due to hydrogen bonding and electrostatic interaction between nanoparticles; adsorption due to quantum tunneling between nanoparticles, charge transfer and local coupling of interface atoms; adsorption due to the huge surface area of nanoparticles adsorption.

2 Dispersion of two nanometer powder

In order to disperse nanoparticles, it is necessary to enhance the repulsion between nanoparticles: strengthen the wettability of the surface of the nanoparticles to the dispersion medium, change the interface structure, increase the strength and thickness of the solvated film, and enhance the repelling effect of the solvent; The absolute value of the potential of the electric double layer on the surface of the nanoparticles enhances the electrostatic repulsion between the nanoparticles; the polymer dispersant is adsorbed on the surface of the nanoparticles to produce and strengthen the three-dimensional protection.

2.1 Physical dispersion

(1) Mechanical dispersion

Mechanical dispersion is a method of dispersing nanoparticles in a medium by mechanical energy such as external shearing force or impact force. In fact, this is a very complex dispersion process, which is achieved by applying mechanical force to the dispersion system, causing changes in the physical and chemical properties of the substances in the system and accompanying a series of chemical reactions to achieve the purpose of dispersion. This phenomenon is called mechanical chemical reaction.

Mechanical dispersion methods include grinding dispersion, ordinary ball mill dispersion, vibration ball mill dispersion, colloidal mill dispersion, air mill dispersion, and mechanical high-speed stirring.

(2) Ultrasonic dispersion

Ultrasonic dispersion is an effective method to reduce the agglomeration of nanoparticles. Using local high temperature, high pressure or strong shock waves and micro jets generated during ultrasonic cavitation can greatly weaken the nano-action energy between nanoparticles and effectively prevent nano-particle agglomeration. To make it fully dispersed, overheated ultrasonic stirring should be avoided, because with the increase of thermal and mechanical energy, the probability of particle collision increases, which will lead to further agglomeration. Therefore, the minimum ultrasonic dispersion method should be selected to disperse the nanoparticles.

(3) High-energy treatment method

This method uses high-energy particles to generate active points on the surface of the nanoparticles, increasing the surface activity, making it easy to chemically react or attach to other substances, and to modify the surface of the nanoparticles to achieve the purpose of easy dispersion. High-energy particles include corona, ultraviolet light, microwave, plasma rays, etc., which cause the surface of nanoparticles to be excited to produce active spots.

2.2 Chemical dispersion

(1) Surface chemical modification

Through the chemical reaction between the surface of the nanoparticle and the treatment agent, the surface structure and state of the nanoparticle are changed to achieve the purpose of surface modification, which is called the surface chemical modification of the nanoparticle.

①Coupling agent method

A coupling agent with an amphoteric structure, a part of the groups in the molecule can react with various functional groups on the surface of the powder to form a strong chemical bond, and another part of the group can undergo certain chemical or physical reactions with the organic polymer Entangled.

②Esterification reaction

The reaction between metal oxides and alcohols is called esterification. To modify the surface of nanoparticles by esterification reaction, it is important to make the original hydrophilic and oleophobic surface into a lipophilic and hydrophobic surface. The modification of this surface function is very important in practical applications.

③Surface graft modification

The surface groups of the nanoparticles are used to form chemical bonds with reactive organic compounds to form nano-organic grafted compounds. The solubility of the organic branched compounds in the organic medium is used to enhance the dispersion of the nanoparticles in the organic medium.

(2) Dispersant dispersion

It is mainly through dispersing agent adsorption to change the surface charge distribution of particles, resulting in electrostatic stabilization and steric barrier stabilization to achieve the dispersion effect. There are three main mechanisms.

① Electrostatic stabilization mechanism

In the electrostatic stabilization mechanism, after the charged particles are dissolved in a polar medium (usually water), an electric double layer is formed on the interface between the solid and the solution. When two such particles collide, a repulsive force is generated between them, thereby keeping the particles separated. By adjusting the pH value of the solution, increase the charge of the particles and strengthen their mutual repulsion; or add some substances that can be electrolyzed in the liquid, such as sodium hexametaphosphate, sodium chloride, potassium nitrate, and sodium citrate. The ions produced by the electrolysis of these electrolytes selectively adsorb the nanoparticles, so that the particles are positively or negatively charged, so that in the Brownian motion, the two particles collide with each other to produce a repulsive effect, prevent agglomeration from occurring, and achieve particle dispersion.

②Spatial stabilization mechanism

The high molecular polymer is adsorbed on the surface of the nanoparticle to form a layer of high molecular protective film, which surrounds the nanoparticle, extends the lyophilic group into the water, and has a certain thickness. This shell layer increases the maximum distance between the two particles. The close distance reduces the interaction of van der Waals gravitation, so that the dispersion system can be stabilized. When the particles adsorbing high molecular polymers are close to each other, there will be two situations: the adsorption layer is compressed and does not penetrate each other; the adsorption layer can penetrate each other and overlap each other. Both of these conditions lead to an increase in system energy and an increase in free energy. In the first case, the entropy-repulsive potential energy is generated due to the loss of structural entropy of the polymer; in the second case, the potential energy of osmotic repulsion and the mixed repulsive potential energy are generated due to the increase of the concentration in the overlapping area. Therefore, it will be very difficult to reunite the nanoparticles that have adsorbed the polymer, thereby realizing the dispersion of the particles.

③Dispersion mechanism of electric steric barrier

In the aforementioned circumstances, if the polymer is a polyelectrolyte, it can play a dual stabilizing effect at a certain pH value. This situation is called the electric steric barrier dispersion mechanism.