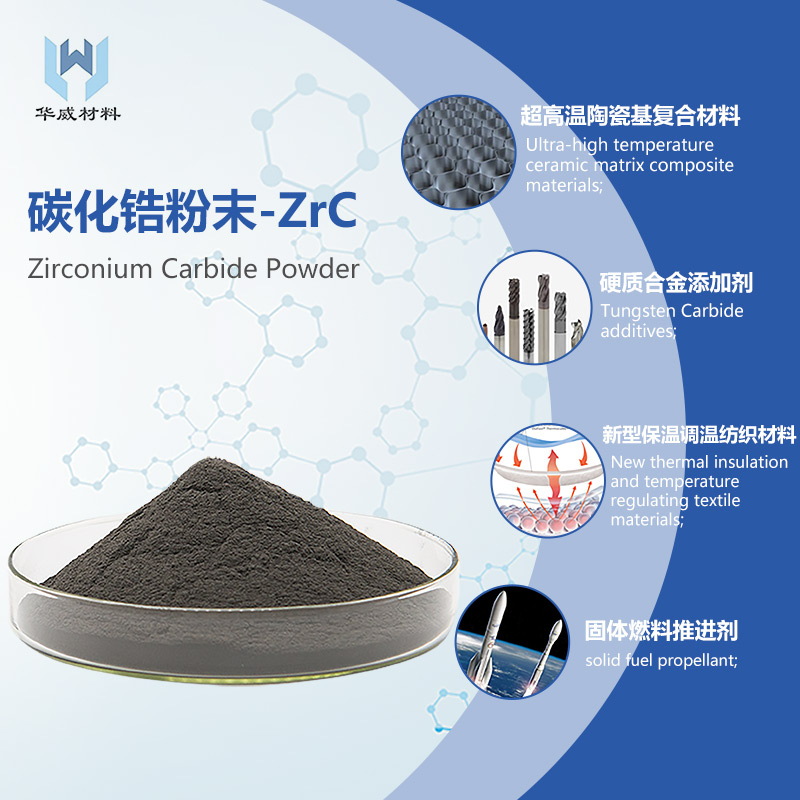

Zirconium carbide (ZrC) is an important high temperature structural material with high melting point, high strength and corrosion resistance, and it can absorb visible light absorption , infrared reflection and heat storage at high efficiency, etc., which is widely used in aviation, aerospace, metal ceramics and new thermal insulation and temperature control textile and other fields.

1, Carbon composite functional material modifier - zirconium carbide (ZrC) : zirconium carbide modified carbon fiber can greatly improve the strength of carbon fiber, increase the resistance to fatigue and wear resistance and high temperature resistance. At present, it is widely used in the modification of aerospace carbon fiber materials, effecting obviously.After test, all the indexes of modified carbon fiber surpass the foreign level.

2, Zirconium carbide (ZrC) applied in the field of new thermal insulation temperature textiles: zirconium carbide with high efficient absorption of visible light, reflected infrared characteristic, when it absorbs 95% of the short wave energy from the sun, under 2 microns,after thermal conversion, energy can be stored in the material, it also can reflect the infrared wave lengths, which is more than 2 microns. Since the infrared wavelength produced by the human body is about 10μm, when people wear zirconium carbide modified textile clothes, the human body infrared will not be send out easily. This shows that zirconium carbide has ideal characteristics of heat absorption and heat storage.

3, When zirconium carbide (ZrC) is used in cemented carbide, powder metallurgy and other fields, it can improve the strength of cemented carbide, corrosion resistance and other properties;

4, zirconium carbide (ZrC) can be used as modified agent in rocket, missile solid propellant.

Performance characteristics:

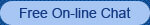

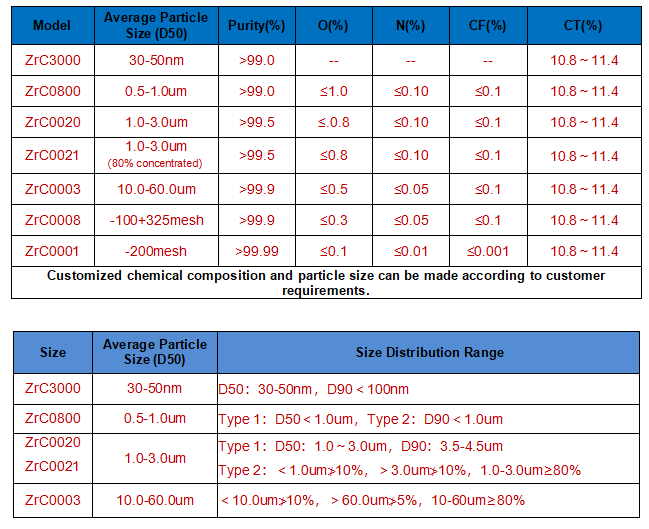

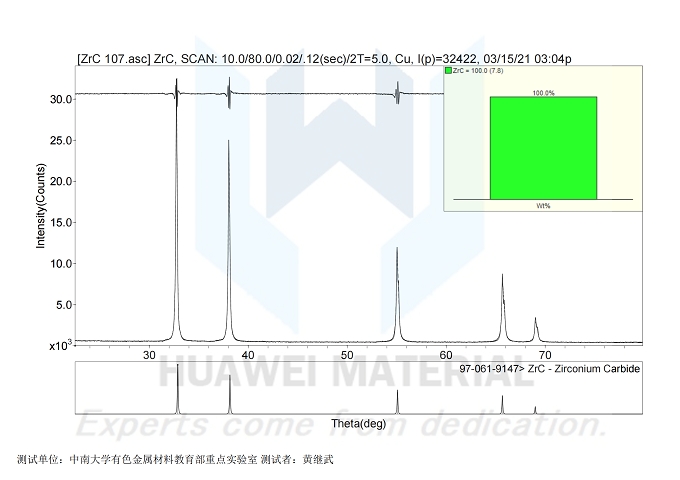

1, High purity: the highest purity can reach 99.99%, XRD detected no impurity phase, GDMS detected low metal impurities content of elements;

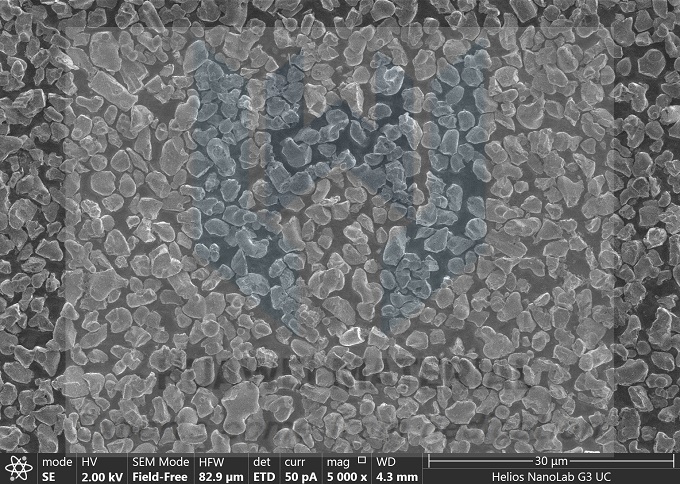

2, Small particle size: the minimum particle size is 30-50nm;

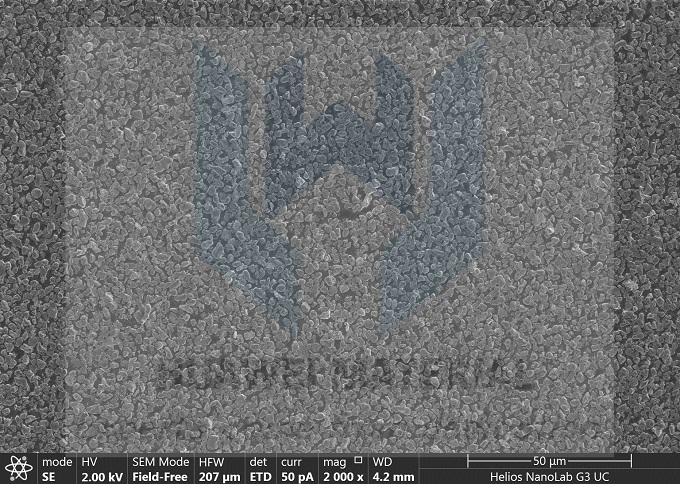

3. Concentrated distribution: standard normal distribution of particle size, no bimodal or multi-modal.

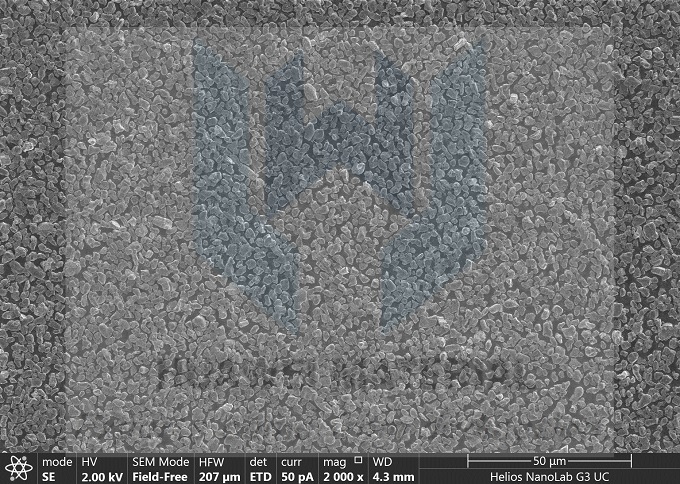

4. Typical Products:

① : standard 1-3um (D10 > 1.0um, D50:1.2 ~ 1.8um, D90 < 3.0um, 80% particle size concentrated in the range of 1-3um)

② : 10-60um plasma thermal spraying cermet powder (D10 > 10.0um, D50:20 ~ 30um, D90 < 60.0um, 80% particle size concentrated in the range of 10-60um)

(Chat Online)

(Chat Online)